MEDVIC 연구실

MEchanical Design and VIbration Control

Research

- HOME

- Research

- Tilting Pad Bearing

Tilting Pad Bearing

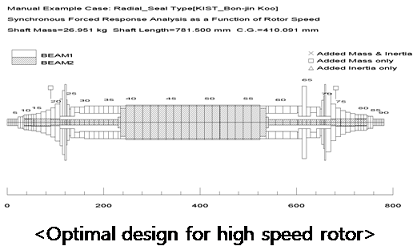

Optimal Design for High Speed Rotor

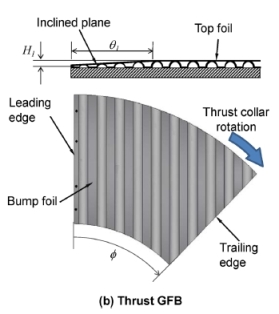

GFBs are a type of the hydrodynamic air bearing with a foil structure (a top foil and a bump foil) between a journal and a bearing housing, as shown in Fig. 2(a). The bump foil provides a compliant bearing surface that deforms under hydrodynamic film pressure, yielding a wider minimum gas-film thickness and thus enhancing load capacity and rotordynamic stability. The bump foil structure is also applied to thrust bearings, as shown in Fig. 2(b). The hydrodynamic film pressure is developed in the inclined plane at the leading edge

Rotordynamic analyses of a rotor-bearing system require dynamic force coefficients of journal GFBs over an operating speed range, usually assuming that the journal GFB is a linear spring-damper system with two degrees of freedom. The dynamic force coefficients of the journal GFBs are calculated from a perturbation analysis, wherein a rotor is perturbed harmonically with infinitesimal amplitudes at an excitation frequency around a static equilibrium position. The rotor excitation induces perturbed motions of the top and bump foils, which are assumed to have zero masses due to their thinness.

High Speed Vibration Control Technology

( Vibration Control of a High Speed Rotor Supported by the Combined Smart Bearing)

Combined smart bearing (CSB) integrates two oil free bearing technologies to take advantage of the strengths of each bearing with minimizing each other weaknesses. It is for enhancing dynamic stability and load carrying capacity [1]. Moreover, CSB have a shorter length than size of hybrid bearing suggested by Heshmat in same performance [2]. So, it has the advantage of the design in high speed turbo machinery. This paper presents vibration control of a high speed rotor supported by CSB. An experiment set-up of a rotor bearing system is built. And rotor dynamic analysis of the rigid rotor on critical speeds is performed. For the experimental approach, unbalance responses of the rigid rotor supported by each bearings: air foil bearing (AFB) and CSB are compared to verify the effectiveness of the CSB. First, the PD control parameters of the magnetic bearing were to find out in stable range experimentally. Then according to the angle of unbalance experiments, compared the performance of AFB and CSB. The result, the shaft vibration in a critical speed is significantly suppressed by the CSB rather than AFB.